Design

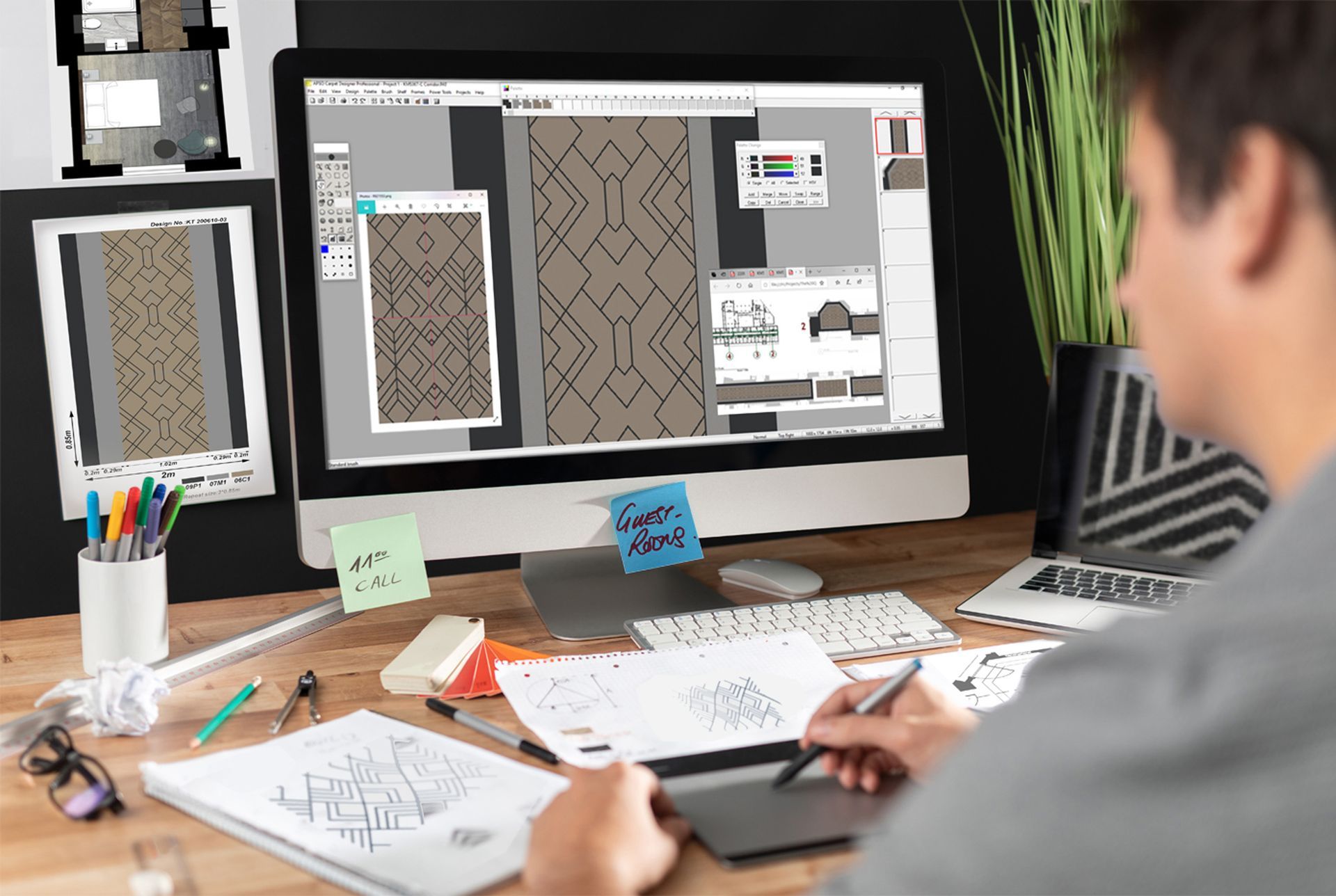

Haima Group Corporation have an extensive design team of over 100 fully qualified and experienced designers to be of service to our clients. We use the latest digital carpet designer technologies within our industry, enabling Haima to create, draft and formulate design proposals for our valued clients.

The Design Process

Our talented teams will guide you through your ideas and specifications, translating every design brief into a presentation of exciting and creative solutions, for your review. Our dedicated designers will work closely with you considering your selected design styling, whether you are looking for a classical traditional scheme right through to a contemporary cutting edge impression.

The initial design process can take inspiration from a sketch, a current concept, new idea or pattern from our expansive historical archive. To bring our designs to life, Haima have an extensive colour bank system of 1500 shades, as well as the ability to custom colour match to any tone or shade you specify.

Our team is ready to inspire and service your design brief, bringing your spaces to life and achieving beautiful backdrops for your hard working floors.

Sampling

When your designs are ready for bespoke sampling the next process is prepared in our specialised laboratories. Haima can offer samples in Axminster kibby, Wire Wilton, Printed Chromojet, Colaris, Tufted, Solution Dyed Nylon and Hand Knitted, Hand Woven and Hand Tufted constructions.

Haima will prepare your sample in the exact specification, design, colour and quality required. The sample will present accurate colour, pattern/texture and scale of your chosen design. If your carpet is a rug design then your sample will be edge finished for final production sign off.

Once your sample is ready to dispatch, we will ensure to keep you updated by tracking your sample, so you are notified when it is due for arrival.

Planning

Haima work with the latest Calidus AutoCAD flooring quantification software packages. With DWG files we will prepare comprehensive floor roll plans showing optimum carpet widths and lengths in order to minimise waste. To achieve this we meticulously plan each area on the best width to not only reduce waste but seams where possible. We can plan for 3.66mtr, 4.00mtr, 4.20mtr, 5.00mtr and also special widths upon request.

Our dedicated designers will scale and draft your selected design into the floor plan area, allowing review of design positioning including central design and border features, corridor turns, and door way entrances.

The installation teams will receive our fully comprehensive roll and seaming plan, enabling them to follow the methodically configured layouts for a perfect fit.

Inspection & Finishing

Haima places this element of corporate governance as their top priority. Haima comply with ISO9001, ISO14001, ISO18001 and hold the CRI Plus certificate. Every sample and manufactured carpet we produce undergoes rigorous quality control.

Samples are made on our micro-manufacturing ( kibby) machines, so each sample is a production quality. When the order is nearing completion, every element of its constituents, composition and construction is double-checked, as our CRI Test Certification dictates. No carpet leaves our plant unless it is signed off as perfect.

As of the time of writing this, in almost 5 years trading, we have never had to entertain a complaint on any quality or carpet made in that timespan. That is why our customers come back to us, again and again. This repeatability process is what sets Haima apart from many other vendors.